Energy Management Systems, Making Information Actionable

Energy management systems (EMSs) have become a popular tool in high performance buildings. You may have heard the term or have some familiarity with the concept; however, a lot of confusion persists in the building industry about what constitutes an EMS and how and when it can be useful.

An EMS is a software platform used to monitor, analyze, control and optimize energy usage and overall building performance. This may include things beyond energy, such as maintaining fresh air, managing equipment before something fails, or simply a place for historical information of what happened.

Significant advancements have occurred over the last decade making the capabilities of these systems much more sophisticated. EMSs have moved past well-established uses towards intelligent devices and adaptive controls; innovation that other market sectors have already started to adopt. Now, an EMS is virtually essential for improving building performance, enhancing occupant comfort, and achieving aggressive carbon reduction goals.

The fact that we can get much more information and value out of an EMS is great news, yet successful utilization is not as simple as plug-n-play. Today, there is no single path for EMS implementation and maximizing the benefits is heavily dependent on how the EMS is integrated into an organization’s processes. With the EMS market rapidly growing, there is a flood of product and service offerings each with different capabilities and solutions, making it extremely challenging to evaluate and find the right fit. There are not a lot of resources available to help owners, engineers, or consultants make this selection, so we felt the topic was long overdue to share some lessons from the trenches. The intent of this blog post is to be a resource to support the adoption of EMS systems.

Acronym Confusion

The first thing that can throw you off is all the terminology and acronyms commonly heard: BMS, BAS, EMS, EMIS, EMCS, EIS, FDD, AMI, Analytic Software, Dashboard, etc. To make matters worse, even the most seasoned veterans in the industry often misuse or interchange these acronyms. Another common misconception is that a Building Automation System (BAS) or Building Management System (BMS)1 is the same as an Energy Management System. News alert, they are not the same.

1 To add more to the confusion, California Title 24 Part 6 refers to an “EMCS” as an analogous system to BAS or BMS.

EMS vs. BAS

A BMS is a system which primarily controls the heating, ventilation, and air conditioning (HVAC) in modern commercial buildings and typically not much else. They can vary widely in complexity, from a simple timeclock with a schedule to a custom set of control logic that is quite elaborate. A BAS could technically be considered an EMS since it can change equipment or system’s operation, such as simply turning off a piece of equipment and saving energy. However, there are significant differences, most notably an EMS makes data “actionable.”

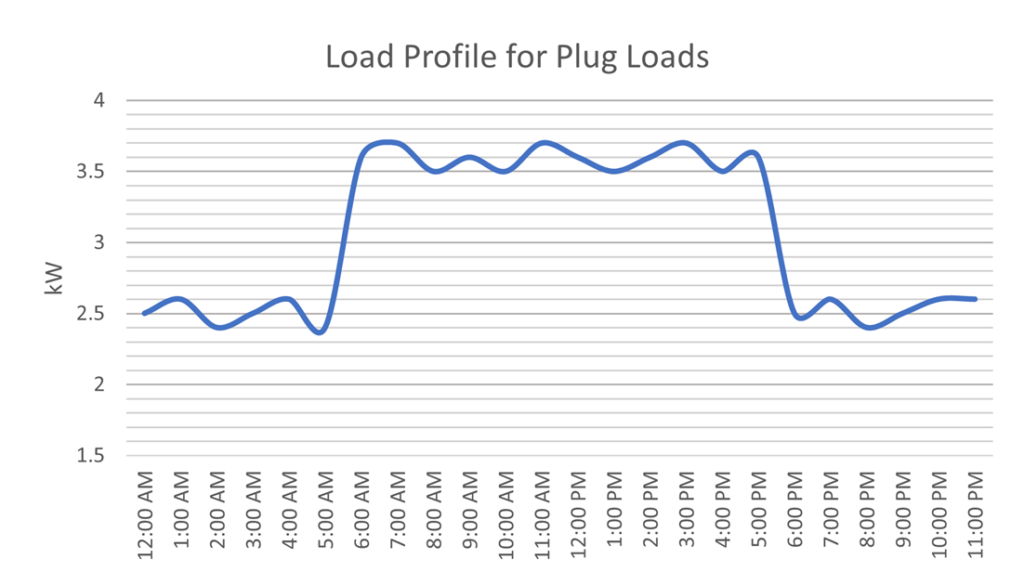

A modern BAS can trend and store interval data for all connected systems or devices. Although this information is important and necessary to understand the performance of a building, the way this information is presented and used provides limited insightful information and often fails to perform any advanced analytics. Figure 1 below shows a typical trend of electric demand data for plug loads over a 24-hour period. After looking at this trend data, are you able to provide any “actionable” items to address?

By contrast, an EMS inherently can identify changes in energy consumption quickly with useful visualizations. In Figure 2, if you took the same data and overlayed it for several days, you should be able to quickly identify the load profile change after an energy efficiency measure was implemented. Making data actionable is just one example of how an EMS differs from a BAS. For more examples refer to our EMS Design Guide found on our website.

Chart: Notice reductions between 12am-5am & 6pm-11pm

Benefits of an EMS

Energy, Demand, and Cost Savings

Achieving improvements through conventional Energy Conservation Measures (ECMs) is an ongoing challenge for many facilities today. Utilizing an EMS can provide opportunities for achieving additional energy reduction goals beyond the low hanging fruit. An EMS can identify many ECMs such as failed components, control sequences that need optimization, as well as scheduling problems.

With the assistance of an EMS, facility operators can easily understand their building’s energy demand profiles, create demand reduction strategies, and then quantify the results. These strategies can even be automated and provide verification that can be shared with management.

A report by Smart Energy Analytics Campaign from October of 2020 found the annual median energy savings for organizations with an EMS to be 3% and 9% for organizations that implemented Automated Fault Detection Diagnostics (AFDD). Compared to the first-year investment cost of installation and software of $0.08 per sq foot, the systems achieved a 2 year payback.2 Recognizing the value of an EMS, many utilities are offering rebates and other incentives to encourage use of these systems..

2 Energy Management Information Systems Technical Resources Report; U.S. Department of Energy; July 2021

Achieve Persistent Performance

Getting the most energy savings out of an HVAC system requires dynamic components and controls capable of adjustment, such as variable speed drives, or demand limiting controls, as opposed to simple on/off control. These strategies often add a higher level of complexity, making it challenging to maintain persistent energy savings over time, often resulting in systems slowly going off target or in other words, performance tends to drift. Additionally, facilities staff often have difficulty understanding the control logic and operations and maintenance (O&M) requirements due to many reasons such as:

- lack of training of the operational intent as a holistic system

- the need for very specific skills to make logic adjustments, and

- black box or proprietary controls that are not visible.

An EMS is the best tool currently to achieve persistent performance in buildings by analyzing massive amounts of data continuously and identifying problems with having little knowledge of the control logic or building system configuration.

Meet Compliance Requirements

Many different building codes, certifications, or local ordinance’s are now requiring buildings to be capable of ongoing visibility into energy use and operations which often leads to a need for an EMS. Some examples include:

- LEED V4 – Option 1, Path 2 of the Enhanced Commissioning credit “monitoring-based commissioning,” which integrates three components: permanent energy monitoring systems, real-time energy analysis, and ongoing commissioning. The purpose and function of an EMS can satisfy this requirement.

- City Ordinance Energy Benchmarking – cities throughout California (e.g., San Francisco, Berkeley, San Jose, Los Angeles, and San Diego) have their version of ordinances that require some level of building energy benchmarking and “energy assessments.” The reporting features of an EMS can assist in these efforts.

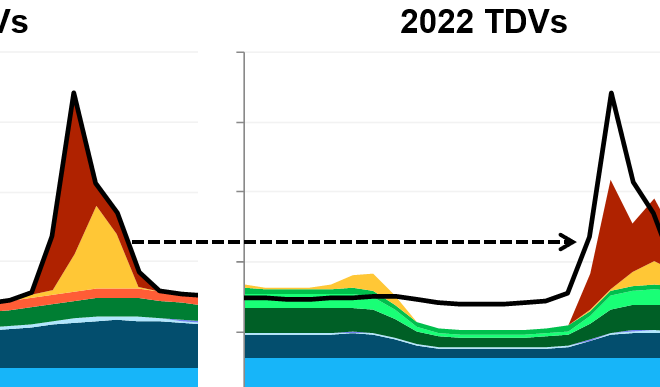

- Building Energy Standards – Such as ASHRAE 92.1/ISO50001 – ASHRAE Standard 90.1-2019 requires submetering of total electricity use, HVAC systems, interior lighting, exterior lighting, and receptacle circuits (ASHRAE 2019a). As local code jurisdictions work to adopt the latest version of ASHRAE 90.1, it will become standard practice to construct and design new buildings with individually submetered end-use loads. Required submeters can be tied into the EMS for interval meter analytics and to process this large quantity of submetered data.

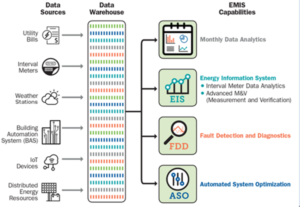

EMS Capabilities

EMSs are evolving very quickly primarily due to the low cost of data storage and computing, advancements in data analytics, and internet connectivity of the end-use systems beyond just HVAC such as occupant presence detection, lighting controls, energy meters, etc. Below are the most common capabilities you will find in an EMS:

- Centralize, Normalize, Visualize Data—Automatically bring data streams together from different sources into a common database. Translate the data in a visual context, such as a chart, to make data easier to understand and present insights.

- Utility Bill Management—Track, understand, and process data from utility bills.

- Interval Meter Analytics—Automate the capture of “real-time”, high-resolution meter data and leverage sophisticated analytical tools to document a building’s energy-usage patterns.

- Measurement & Verification—Identify, quantify, and verify the energy savings performance of individual energy conservation measures or efficiency projects.

- Automate Fault Detection Diagnostics (AFFD)—Automatically detect equipment-level or system-level performance and operational issues and diagnose their causes.

- Supervisory Control—Perform automated controls changes to underlying building systems for optimization.

- Operation & Maintenance (O&M) Optimization—Provide tools to integrate the above capabilities with O&M processes to increase efficiency.

What EMS Features are Right for My Building?

You may be wondering “can all buildings, small or simple or existing or ones without a BMS, benefit from an EMS?”

Installing an EMS does have a minimum cost regardless of the square footage, which can make the return on investment less attractive. However, there are definitely solutions that work and are beneficial to these types of buildings. For example, a small building can benefit from end-use building interval meter data analytics but may not necessarily need the more sophisticated capabilites such as Automated Fault Detection Diagnostics. Or, a small building that is complex might be trying to achieve a performance outcome such as Zero Net Energy. In this case the EMS capabilities will differ and would likely include end-use submetering and advanced analytics. In the planning phase, the capabilities of the EMS should be considered. In larger facilities with more complex building systems, the EMS capabilities will be different from a smaller facility. There is not a one-size fits all.

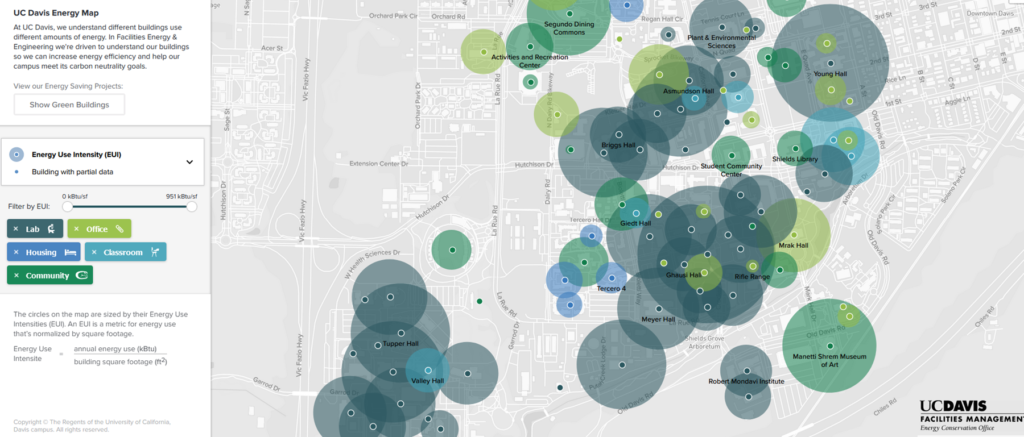

On the flip side, clients that have multiple buildings or portfolios can benefit from the fact that EMS systems can scale. You have the ability to compare buildings across the portfolio and easily identify which buildings have the most potential for energy savings. An EMS from UC Davis is shown in Figure 4 below and provides a great visulatization of energy use intensity by building on the campus. Analyzing the data can have endless possibilities, such as comparing all of the chillers across a campus by the number of work orders or equipment failures by manufacturer. These capabilities go beyond energy efficiency; they can help procurement when replacing equipment or measuring other metrics that are important like water usage, waste diversion, etc.

EMS Selection Considerations

The table below highlights a few considerations for the planning process following the decision to integrate an EMS into the design of a building project.

| Design / Construction Considerations |

|

| Commissioning Considerations | Include commissioning scope to ensure all meters and systems giving data are properly commissioned to ensure the EMS gets good data. |

| Operations Considerations | Ownership team member training to understand functionality of system and how to respond to the information that EMS presents. |

How Do I make an EMS effective for my Building?

A challenge for many owners or engineers is understanding what makes an EMS effective. Below are a few examples of some pitfalls often encountered:EMS system is not tailored to the correct audience or, the operational users are not involved in the design

An EMS is designed to allow a more efficient way for users to manage, analyze, and interact with data. Typically, the design of the user interface varies with the product, with some products allowing the user to customize the EMS. It is important to always keep in mind who will be using the EMS. Some facilities prefer to use one standard interface for all users, while others find it useful to modify the interface based on the user’s individual role. Energy managers are often more concerned with energy metrics whereas facility supervisors may want more information on O&M metrics. Historically, EMSs have been used primarily by sustainability or energy managers though recently the addition of AFDDs and advanced analytics tools make an EMS an asset to aid building engineers or maintenance staff in their duties.Key Performance Indicators (KPIs) are not defined

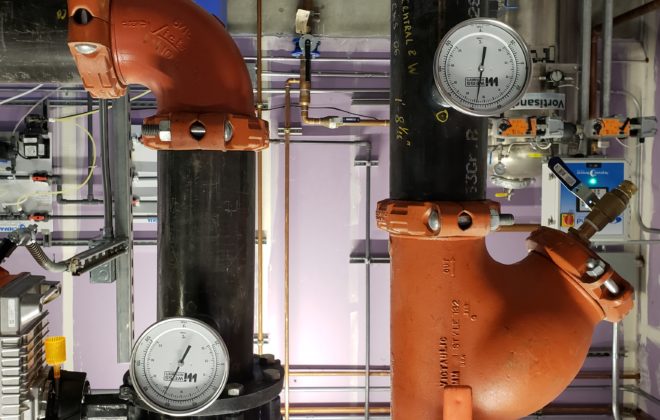

A KPI is a metric that can be tracked and compared to historical or expected performance values and help to identify when systems deviate and require corrective action. A KPI metric can combine data from multiple points which is quite different from a BAS which typically just tracks thousands of points individually. A KPI metric provides a clearer picture of systems that need attention, identifying irregularities or anomalies. An example KPI is chiller plant efficiency, which is measured through the coefficient of performance (COP): total thermal tons of chilled water produced divided by the electrical input to the plant. This KPI can be monitored daily and historically to help make decisions about the plant’s operation, such as “how many chillers should we run?” or “does it make sense to run a single chiller up to full capacity and bring on a second?” Each organization will have unique KPIs that are important to them. It is important to identify these KPIs as early as possible to ensure the correct hardware, software, and infrastructure are present to collect the necessary data to measure and report them.Lack of knowledge about how the data could or should look and reinventing the wheel

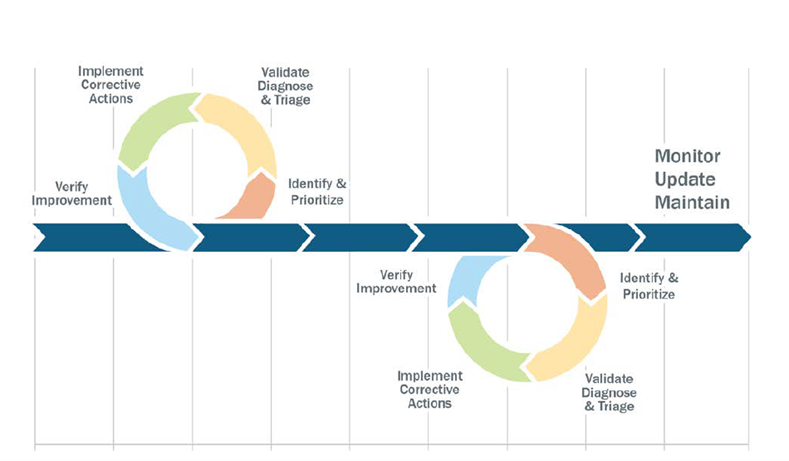

The information buildings can generate on how they use energy or how systems are functioning can be highly useful if it can be clearly presented and understood. The challenge most often is knowing what types of building monitoring options even exist and figuring out how best to bring the right information to the right people. Visualizations allow users to spot patterns in the data that would be difficult to see otherwise. This drastically reduces the time required to analyze the data or create reports. But how do you know what visualizations would be best for your EMS? That is not an easy question to answer for most. Some owners include several hours of customization with the purchase of their EMS system so that they can come back after they have spent some time operating the building and understanding the needs. Another approach is to start with a pilot program, this could mean starting with a single building or a specific system with known performance issues or even comparing two different EMS platforms.Don’t forget the Operations Phase

An EMS is a powerful tool; however, it is not a stand-alone system. An EMS depends upon human interaction to produce the end results. A diverse team needs to convert data into information and insights with the ultimate goal of taking action and verify results. An EMS needs to include an energy management process which identifies roles and responsibilities and gets buy-in from management. Some organizations do not have the staff or infrastructure to create an internal process; one alternative could be to use a 3rd party service provider. There are a few different procurement methods; refer to our EMS Design Guide for a more detailed information. However, if your facility uses an internal team, there needs to be appropriate provisions to ensure proper training for EMS operators on using the EMS platform.